Dean's Message

I could never have predicted the way my first year as Dean has unfolded.

The unprecedented disruptions brought about by the worldwide COVID-19 pandemic presented challenges for every facet of our Faculty’s activities, from education to research and innovation.

I have been inspired by the way our community — faculty members, staff, students, alumni, industry partners and supporters — has risen to the challenge.

Drawing on our leadership in technology-enabled teaching, we quickly transitioned our courses, final assessments and even thesis defenses online. We provided our expertise to help the public and government officials understand the direct and indirect impacts of the pandemic. We sewed masks, built apps and developed new techniques for rapid testing. Above all, we kept going, demonstrating the resilience for which our Faculty is known.

In this report, you’ll read about our many achievements from the past year, from setting yet another world record for human-powered vehicle speed, to earning some of Canada’s most prestigious honours for science and engineering research. You’ll see how we continue to grow and diversify our vibrant community — 38% of our undergraduates are now women, and one in four students come from outside of Canada. Our partnerships, collaborations and opportunities for cultural exchange extend across the globe, demonstrating the philosophy of “Engineering for the World.”

There is much more to be done. Though we remain Canada’s top-ranked engineering school, we do not yet reflect the full diversity of the communities we serve. We continue to work toward better representation and to build a more equitable and inclusive Faculty. I hope that as you read about our progress, you are as inspired as I am about the future.

The hurdles we face are daunting, but they underscore the critical role that engineering plays in addressing global challenges and building a better world. I am proud of how our community shines under adversity, and I am optimistic about all that is to come.

CHRIS YIP

Dean, Faculty of Applied Science & Engineering

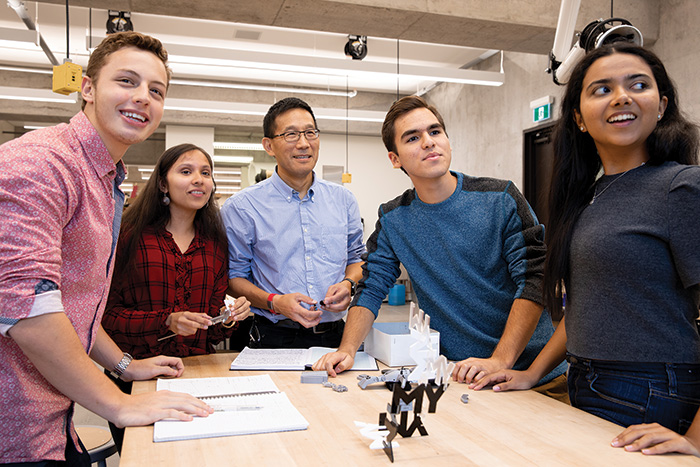

Dean Yip with four of this year’s five Pearson Scholars. (Photo: Roberta Baker)

Engineering for the World

We are nurturing global perspectives among engineering leaders.

For generations, U of T Engineering students have sewn the letters E4TW onto their iconic leather jackets as a reminder of the role they will play in serving humanity.

Below are a selection of members of the U of T Engineering community who embodied the spirit of E4TW in 2019–2020 through a range of initiatives — from research collaborations to capstone projects, exchanges, competitions and internships abroad.

“Expectations of our engineers are greater than ever before,” says Professor Greg Evans, director of the Institute for Studies in Transdisciplinary Engineering Education & Practice (ISTEP). “We are drawing on innovative scholarship to prepare the next generation of leaders.”

Created in 2018, ISTEP is the first institute of its kind in Canada. It combines and enhances our existing strengths and thought leadership in pedagogical innovation and transdisciplinary engineering education.

ISTEP encompasses the following areas:

- The Engineering Communication Program (ECP), a hub for teaching and scholarship in professional communication;

- The Troost Institute for Leadership Education (Troost ILead) in Engineering, which prepares students to maximize their impact and leadership potential;

- The undergraduate-level Engineering Business Minor, the most in- demand of the Faculty’s 10 multidisciplinary engineering minors;

- The undergraduate-level Certificate in Entrepreneurship Innovation and Small Business; and

- The graduate-level Collaborative Specialization in Engineering Education (EngEd) program.

Gaining global perspectives through virtual collaboration

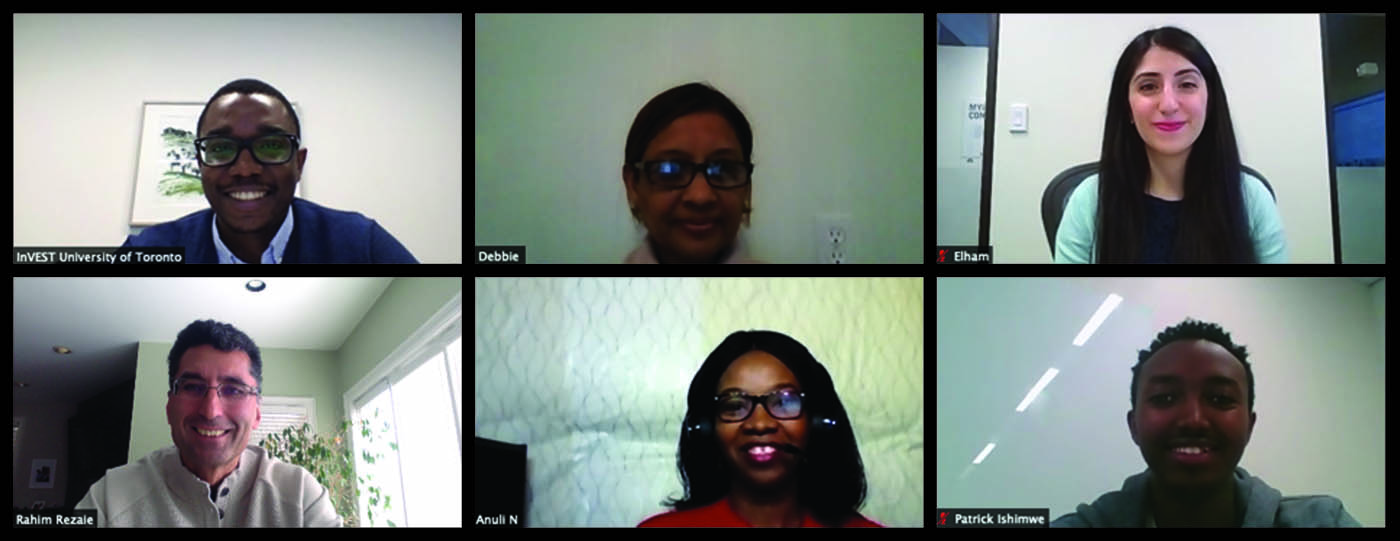

The International Virtual Engineering Student Teams (InVEST) initiative connects UofT Engineering students with their peers at partner universities such as the University of Johannesburg in South Africa, and the University of the West Indies in Trinidad. Teams collaborate via video link on fourth-year capstone courses, MEng research or MASc theses.

“This is a great opportunity to find out first-hand what intercultural collaboration really looks like,” says Dean’s Emerging Innovation in Teaching Professor Elham Marzi (ISTEP) for ISTEP. She and the InVEST team plan to expand their partnerships with at least four new institutions, including: the National University of Singapore, Federal University of São João del-Rei in Brazil, University of Technology Sydney in Australia, and Covenant University in Nigeria.

OPTIONS for PhDs

All professors have a PhD, but in engineering only one in four PhDs become professors. The Opportunities for PhDs: Transitions, Industry Options, Networking and Skills (OPTIONS) program equips PhD students and postdoctoral fellows to explore careers outside academia.

“PhD students in particular are hungry for career advice,” says Professor Julie Audet, vice-dean, graduate studies, who launched OPTIONS in the fall of 2017 in collaboration with Troost ILead.

OPTIONS includes resume workshops, career coaching sessions, panel discussions with recent PhD graduates and alumni mentorship. In the fall of 2019, 30 students completed all requirements of the OPTIONS program, with more than 200 others participating in at least one of its complementary events. A version of the program for MEng students launched in January 2020.

U of T Engineering undergraduates can choose to graduate with up to 20 months of meaningful work experience, a competitive salary, an extensive network and professional skills they’ll leverage for years to come.

That’s what we deliver through the Professional Experience Year Co-op Program (PEY Co-op), our flagship work-experience program with a proven track record going back more than 40 years. Created in collaboration with industry partners and engineering leadership experts, this program is designed to help students build their professional profiles and prepare them for long- term career success.

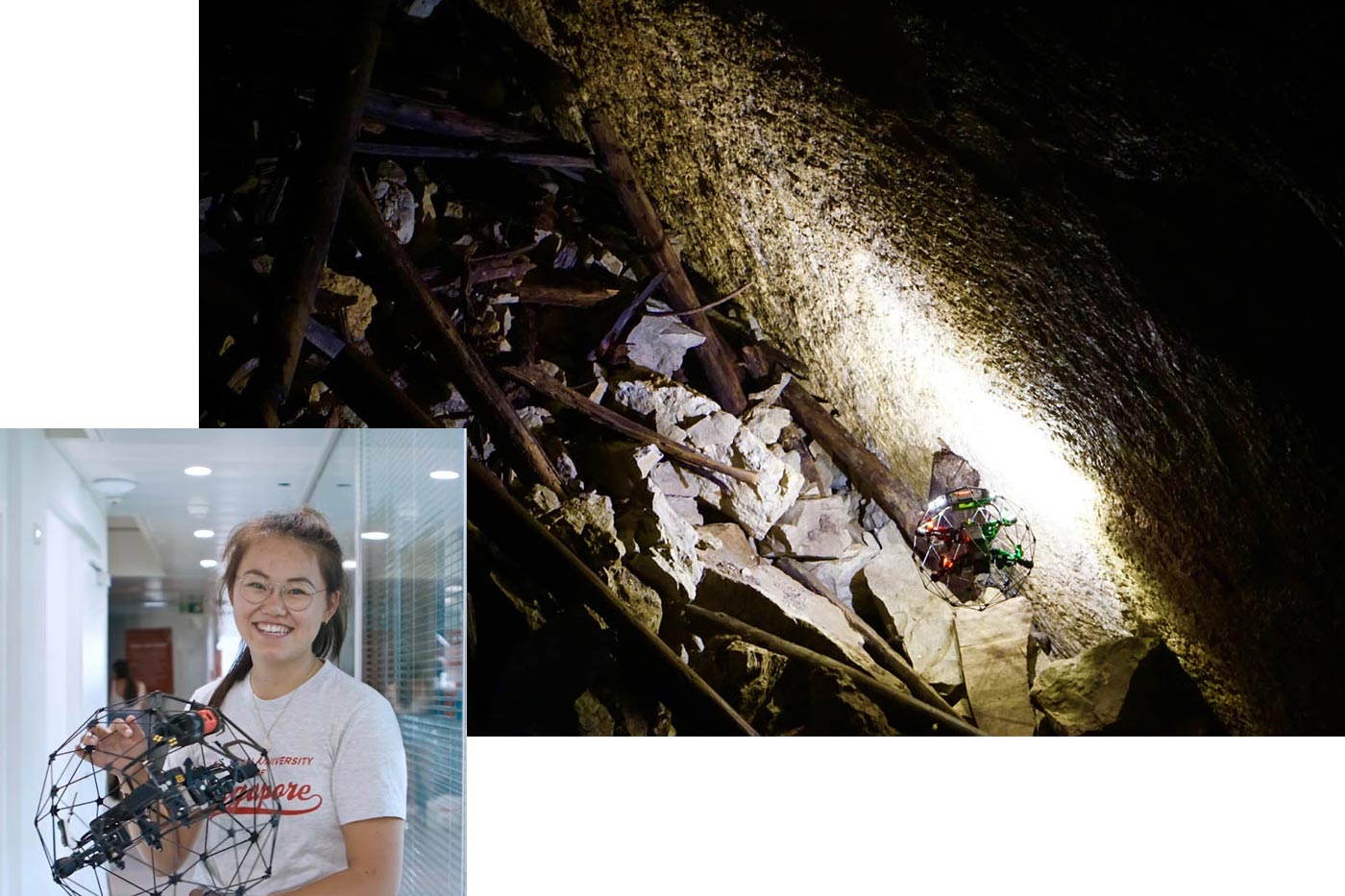

A high-flying experience

Third-year materials engineering student Yilin Huang has two big passions: robotics and world travel. She combined them both when she landed a PEY Co-op position at Flyability, a drone company based in Lausanne, Switzerland.

“I am so amazed at how much I learned from this experience,” says Huang. “Aerodynamic theory, the chemical basis of energy storage in batteries, and which cheeses you should use in a fondue — this is Switzerland after all!”

Huang led a project to test the robustness of propellers for the company’s drones, which are used to do indoor inspections of large or complicated structures in industries from oil and gas to power generation. She also got to spend weekends improving her skills in French and skiing.

Huang was one of more than 700 students employed with leading companies through PEY Co-op in 2019–2020. Dozens of them worked outside of Canada, and many returned to complete their final year with a job offer already in hand.

Her PEY Co-op experience convinced Huang that robotics is the right fit for her, and she plans to pursue graduate studies in the field. But it also taught her something else.

“I learned that it’s not just the experience and knowledge I bring, it’s the attitude,” she says. “Moving forward, I will bring a determined willingness to learn, and I won’t forget to bring my happiness too.”

A new home for the Engineering Career Centre

As PEY Co-op celebrated its 40th anniversary in 2019 and the Engineering Career Centre developed new programming to expand its model, the office was also preparing to move into a new, modern space.

“This new facility has everything we need to expand our flagship program and enhance our offerings,” says Roger Francis, executive director of the Engineering Career Centre. “It offers a home base on campus for our partner companies, and a one-stop-shop for everything students need to launch their careers, from professional skills development to building their network.”

The passion for turning good ideas into viable businesses runs deep in the U of T Engineering community. Whether they are looking to commercialize a research discovery or simply address an unmet market need, we provide our students with the resources, tools and support they need to launch and sustain vibrant companies.

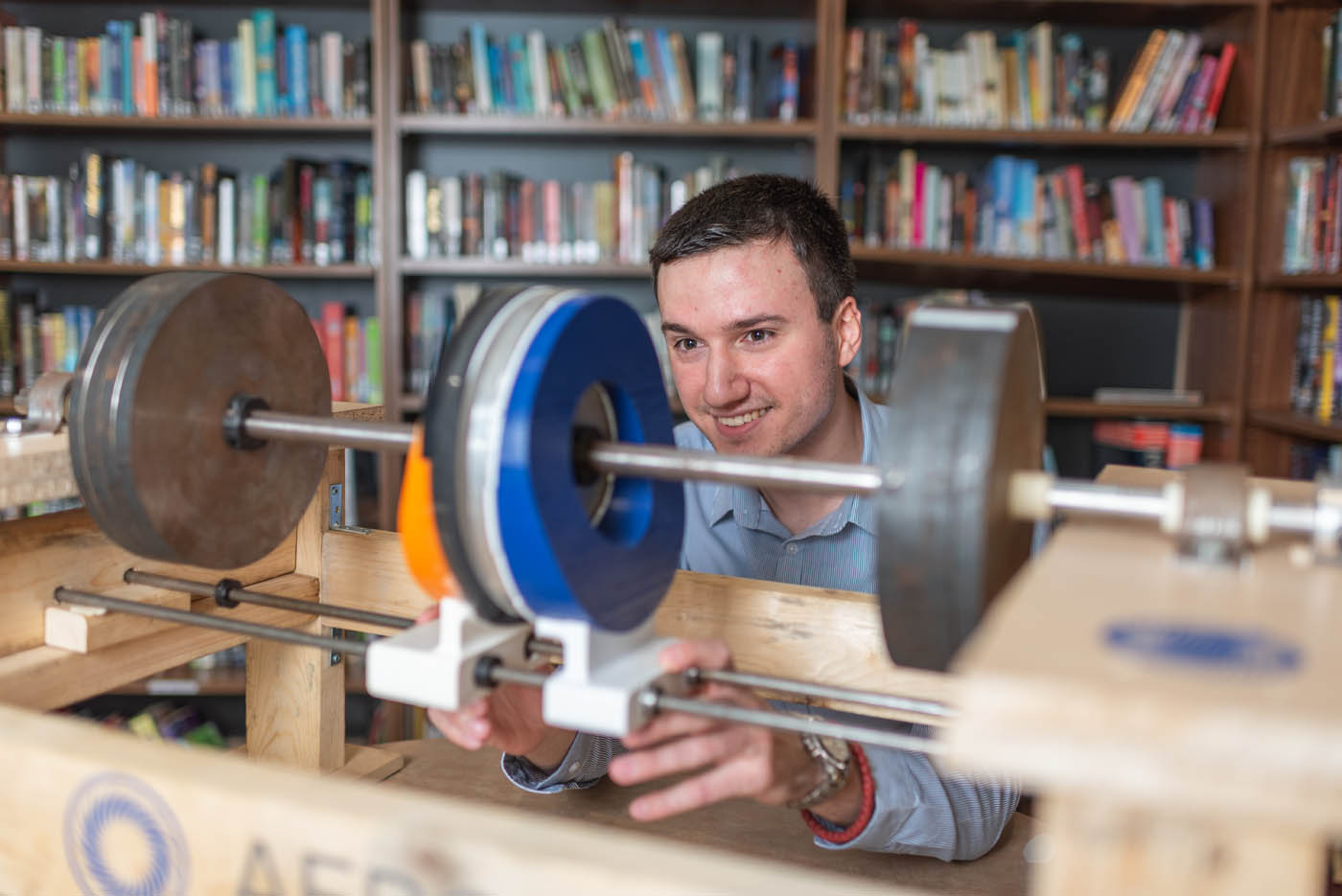

Magnetic brakes could save airlines millions

Every time a commercial airliner lands, more than 50 tonnes of steel, fuel, cargo and passengers come screeching to a halt. The friction takes a toll on the brakes, which must be replaced dozens of times over the course of a typical airplane’s lifetime — but a team from U of T Engineering may have solved that problem.

“We’ve created a special type of magnetic field generator that allows for a major improvement to existing non-contact braking technology,” says mechanical engineering alumnus Nikola Kostic, co-founder of Aeroflux. “Our system eliminates the wear and maintenance of aircraft braking systems, and could help airlines save millions of dollars per plane.”

At The Entrepreneurship Hatchery, a startup incubator at U of T Engineering, the Aeroflux team gained access to mentors who helped them hone their business plans and pitch presentation.

In September 2019, Aeroflux placed first at the annual Hatchery Demo Day live pitch competition. The team also received the Clarke Prize from the Troost Institute for Leadership Education in Engineering, ranked in the global Top 20 for the 2019 James Dyson Award international design competition, and took first place in the Late Stage Competition of the 2020 RBC Prize for Innovation and Entrepreneurship at U of T.

“Our team is so grateful for the support we’ve had from the Hatchery and the entire U of T entrepreneurship ecosystem,” says Kostic. “It’s a big part of the success we’ve had so far.”

We enable our students to see first-hand how engineering can impact communities around the world. Last year, we facilitated 245 international experiences among undergraduate students, from study-abroad programs to international capstone projects.

Power for the people

In Cerro Azul — an isolated mountain community in Costa Rica — the local school has plenty of donated computers, printers and projectors, but the electricity to power this equipment is supplied by a gasoline-fuelled generator which only runs for a few hours each day.

Fourth-year electrical and computer engineering student Diego Amores

and his mechanical engineering team members Shafiul Ferdous and Zarak Khan designed a solar panel installation which they hope will provide more consistent and reliable power. The project was part of a fourth-year capstone course at U of T Engineering, and also counted toward the certificate in Global Engineering that Amores is pursuing.

“I am from Ecuador, and I have witnessed first-hand the challenges people face in developing countries,” says Amores. “I decided that I would love to work on a project that could generate a positive impact for somebody who lacks fundamental services.”

The project’s various partners include U of T Engineering’s Centre for Global Engineering, the Canadian non-profit organization Students Offering Support and the development charity Reto Juvenil Internacional, which has many strong connections in Latin America. Throughout the project, the team was advised by engineer and entrepreneur John Shoust, a co-founder of Winds of Change, which has been involved in several previous projects in places such as Pedro Arauz, Nicaragua.

“I am always impressed by the student teams,” says Shoust. “They all seem to share the common goal of helping in any way they can. I think this is critical in the development of the future workforce, in that they gain a global perspective and understand the impact they can have on the lives of others.”

“I feel really grateful for this opportunity and I would like to encourage more engineering students to create a positive impact through these kinds of projects,” says Amores.

Robots go where people can’t — under water, in the air, even into outer space. They already work alongside humans in factories, and in the future, they may do the same in new settings, such as hospitals and long-term care homes.

U of T Engineering researchers are leading efforts to make robots more resilient, adaptable and responsive to human needs. Their work enables us to use these amazing tools to enhance the quality of life for people everywhere.

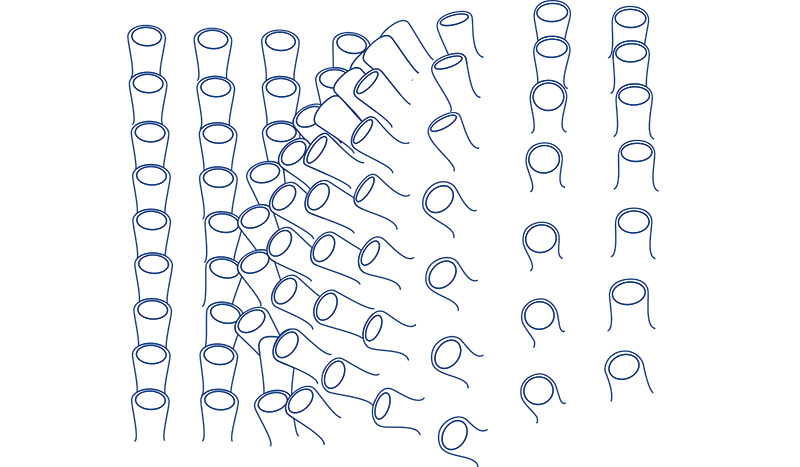

Octopus-inspired grippers for prosthetics and more

The latest innovation from the lab of materials engineering professor Benjamin Hatton was inspired by an unusual source: an octopus.

Hatton and his team are interested in developing new materials with unique surfaces that can actively change their properties in response to stimuli. One model is the ability of an octopus to modify the grip of its tentacles. The team is designing smart pads that can be digitally controlled for dynamic adhesion. By moving microscale surface features on the small pad, they hope to mimic the on-off adhesion of individual octopus suckers.

“We are hoping the smart ‘finger pads’ can help robotic grippers grasp more efficiently,” says Hatton. “Current gripper designs, such as prosthetic hands, have limited control at the material surface, which generally leads to objects slipping or being crushed.”

Hatton and his team plan to use these smart pads to increase sensitivity and dynamic control of robotic grippers. They recently received a Connaught Innovation Award, which will help integrate their work into technological applications within industry, and on a larger scale.

“We appreciate the amazing ability of the human hand to maintain an optimized grip on objects, and constantly change that grip dynamically — all without consciously thinking about it,” says Hatton. “We anticipate this work could improve the designs of prosthetic hands, assistive robotic arms and surgical robotics.”

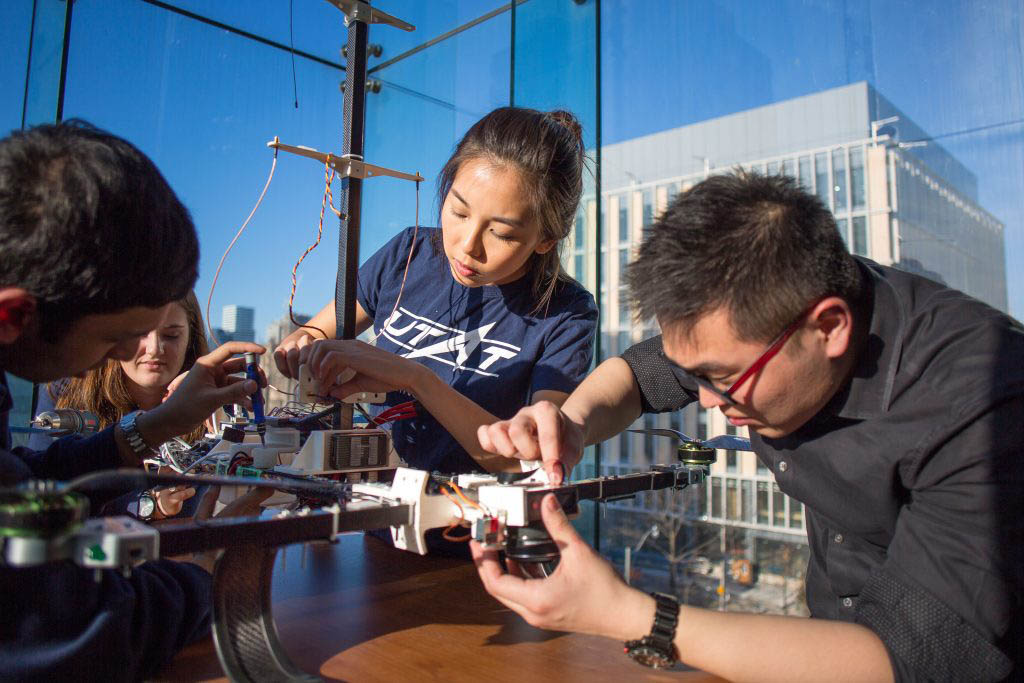

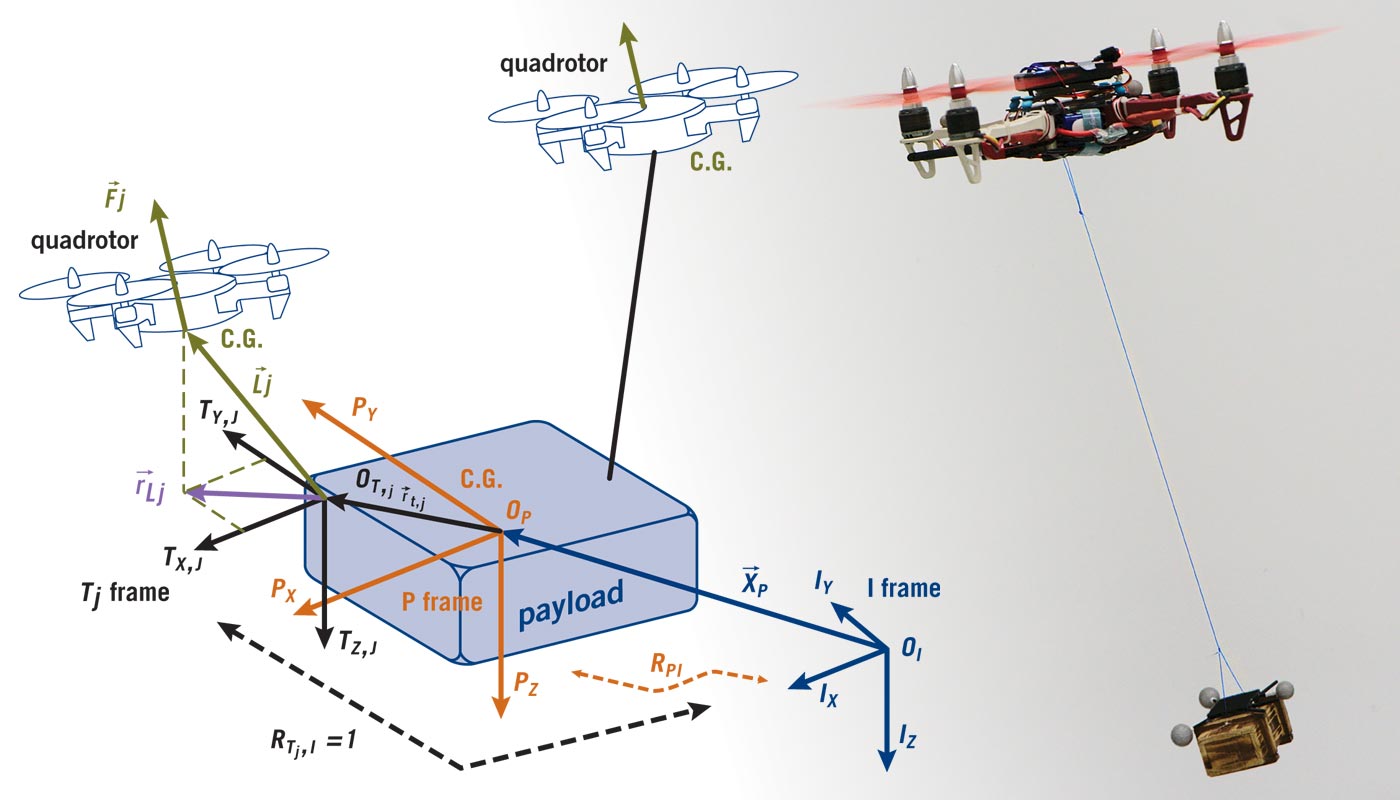

Drone delivery for remote communities

Canada is home to hundreds of remote communities that lack roads — which makes delivering basic consumer goods very costly. Unmanned aerial vehicles (UAVs), also known as drones, could offer a way forward, and Drone Delivery Canada (DDC) has partnered with U of T Engineering to make it happen.

“Our partnership with DDC is now in its third year, and the benefits have been enormous,” says aerospace engineering professor Hugh Liu. Liu and his team are working alongside DDC on coordinated drone delivery, in which groups of small, modular drones would carry and deliver larger packages than any of them could individually. He recently filed a joint patent with DDC related to the technology, and several graduates of his lab group now work for the company.

In addition to Liu’s work on the hardware side, DDC is also collaborating with two professors from the U of T Institute of Aerospace Studies: Tim Barfoot and Angela Schoellig, who holds the Canada Research Chair in Machine Learning for Robotics and Control. Together, they are working on algorithms that would enable a drone to fly back safely to its launch site even if its satellite connections are not functioning.

There is no planet B. Climate change, pollution and environmental degradation are among the most complex global challenges of our time.

U of T Engineering researchers are world leaders in developing new ways of generating and storing energy — techniques that lower or even eliminate emissions. They are also pursuing efforts to design smarter cities by more accurately accounting for the environmental impacts of large infrastructure, and by quantifying the effects of behavioural changes around cycling, public transit, and freight transportation. Together with our industry partners, we are building a cleaner, greener world.

Out of thin air

Rising global CO2 emissions have produced a climate crisis. But what if there was a way to capture emissions before they reach the atmosphere — or better yet, extract the carbon that is already there — and turn it into commercially valuable products?

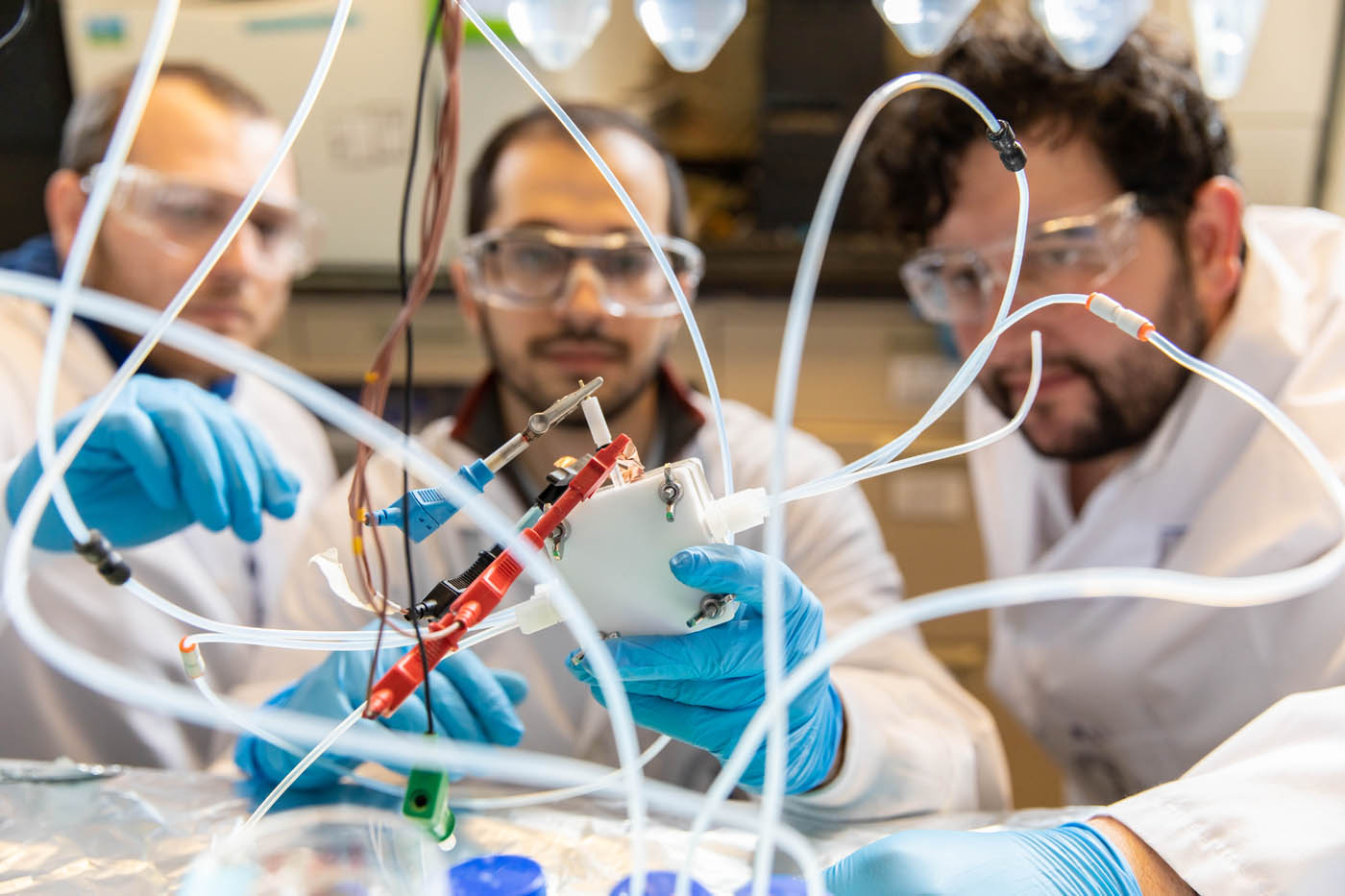

“There are several established chemical pathways for capturing carbon and converting it into fuels or plastic precursors,” says electrical and computer engineering professor Ted Sargent, who holds the Canada Research Chair in Nanotechnology and serves as U of T’s vice-president, research and innovation and strategic initiatives. “The challenge is that they are energy- intensive. Our work focuses on ways to lower this energy cost.”

In the past year, Sargent and his team have published several major papers on the use of electrolyzers — devices that use electricity to drive a chemical reaction — to recover value from waste carbon.

With international collaborators, the team has developed highly efficient electrochemical processes for converting CO2 into ethylene, one of the world’s most widely produced chemicals. They have also used electrolyzers to upgrade ethylene to ethylene oxide, the next step in several complex chemical value chains that eventually end with products such as polyester fabrics and plastic drink bottles.

Shifting delivery times for faster, cleaner transportation

Delivering goods in a busy city has always been a challenge, but today the pressure is higher than ever before.

“It’s the Amazon effect,” says civil engineering professor Matt Roorda, who holds the Canada Research Chair in Freight Transportation and Logistics. “People are buying things online and expect them delivered within a day or even within a few hours.”

Roorda is the lead U of T Engineering researcher on the Smart Freight Centre (SFC), a collaborative network whose partners include McMaster University, York University and the Region of Peel.

Last summer, SFC conducted a pilot study in which industry partners Walmart, Loblaws and LCBO stores shifted key deliveries from daytime hours to the early morning (before 7 a.m.) and late evening (between 7 and 11 p.m.). Roorda and his team found that the shift increased the average speed of trucks by 18%, with associated reductions in key air pollutants of between 10% and 15%.

“There definitely seems to be a lot of spare capacity on our roadways at certain times of day,” says Roorda. “Our pilot study suggests that taking advantage of this could have tangible benefits, both economically and for the environment.”

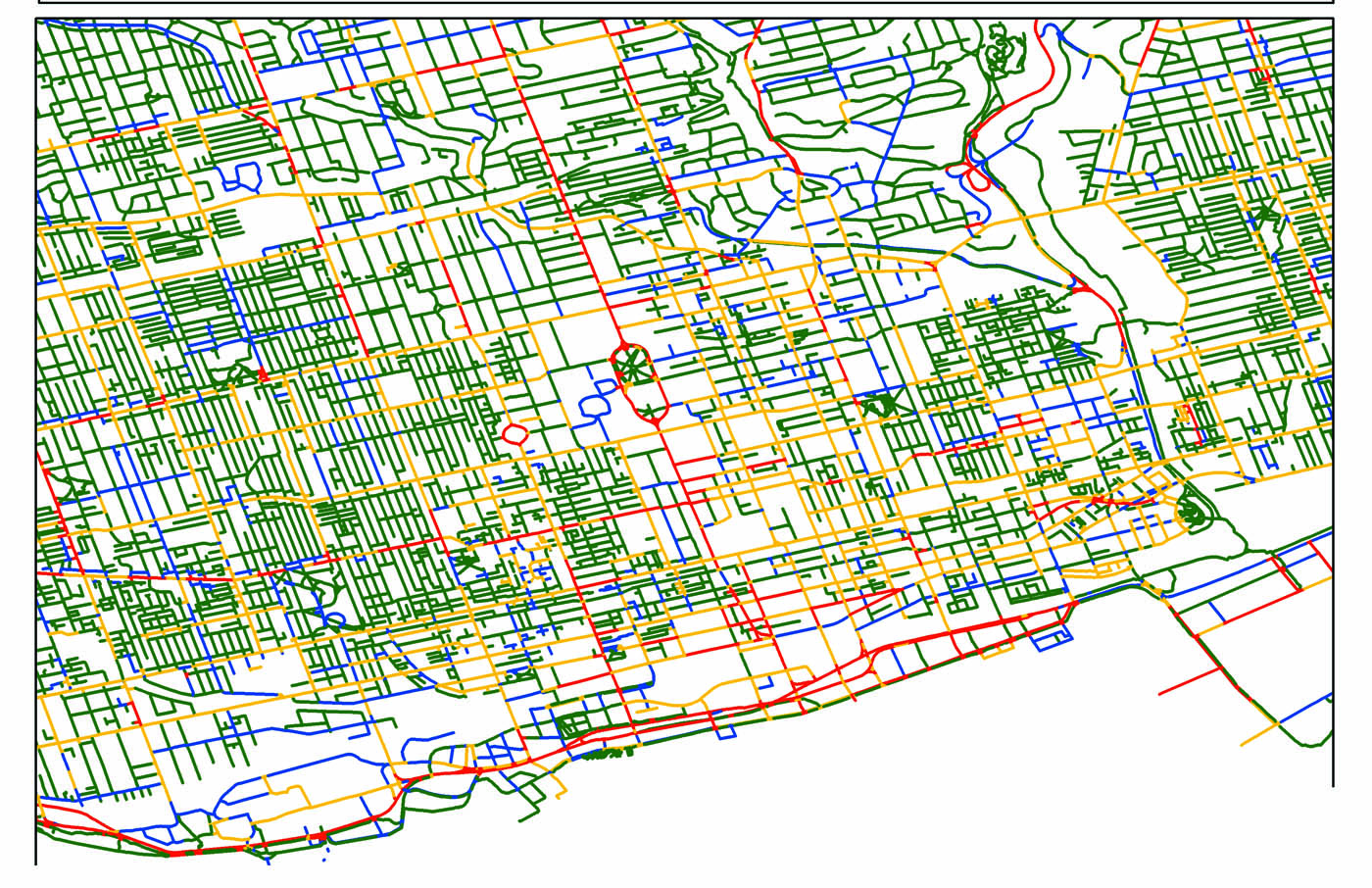

Why don’t more Torontonians cycle to work?

A study led by civil engineering postdoctoral fellow Ahmadreza Imani and professors Shoshanna Saxe and Eric Miller classified nearly every section of road and intersection in Toronto on a scale of one to four by its level of traffic stress, or LTS.

The team found that across most of the city, cyclists cannot travel for more than about eight minutes before hitting a section with an LTS of more than two. If the disjointed nature of Toronto’s cycling infrastructure could be improved, the researchers estimate that the number of citizens cycling to work would rise significantly. The results: improved sustainability and public health.

The rise of deep learning and machine intelligence are driving us to re-imagine almost every sector of our society, from finance to human health to transportation. Big data helps us see patterns, identify bottlenecks and design more efficient systems.

Through hubs such as our Centre for Analytics and Artificial Intelligence Engineering (CARTE), U of T Engineering researchers are working with a range of partners to design new algorithms that can enable autonomous vehicles to navigate safely, improve the delivery of health care and much more.

Can self-driving cars handle a Canadian winter?

A new dataset created by U of T Engineering, the University of Waterloo and Scale AI will help train future self-driving cars to handle the challenges of winter driving.

“Existing datasets were collected on sunny, summer days,” says aerospace engineering professor Steven Waslander. “If you take algorithms trained on those datasets and try to use them in adverse conditions, they tend to get confused.”

In collaboration with Professor Krzysztof Czarnecki (University of Waterloo), Waslander and his team used the Autonomoose — a Lincoln MKZ vehicle equipped with sensors — to record data from more than 1,000 kilometres of driving around southeastern Ontario. Of this, approximately 33 kilometres in harsh, snowy conditions were selected to form the basis of the dataset.

The team partnered with Scale AI, a San Francisco-based AI infrastructure company, to label the data and have made the results available for free to researchers. Waslander and his team also plan to use the dataset in their own work.

“We hope that the techniques we develop to locate and track objects in adverse weather will eventually be incorporated into future autonomous vehicle software packages around the world, making them safer for everyone,” he says.

An artificial intelligence innovation HQ in Toronto

For artificial intelligence researchers at U of T, starting a new industry collaboration is as simple as crossing the street.

The LG Toronto AI Lab was created in the summer of 2018. Since then, it has catalyzed more than a dozen collaborations between employees of the company and U of T researchers in both engineering and computer science. Applications include the use of visual cameras for object detection and 3D perception, as well as data- driven protection.

Through ‘reverse internships,’ LG staff scientists spend up to four months working in academic research labs, returning to the company better equipped to tackle challenging problems. Researchers from LG’s labs in Korea also have the option to complete a ‘mini master’s degree’ by working alongside U of T Engineering professors to refine their skills and completing a capstone project.

Ontario is one of North America’s manufacturing hubs, and Toronto lies at the heart of this critical network. New materials and manufacturing methods are key to ensuring that the manufacturing sector remains competitive for decades to come.

UofT Engineering innovation can enhance logistics, improve quality and accelerate development of the next generation of products, businesses and industries.

Graphene doesn’t crack under pressure

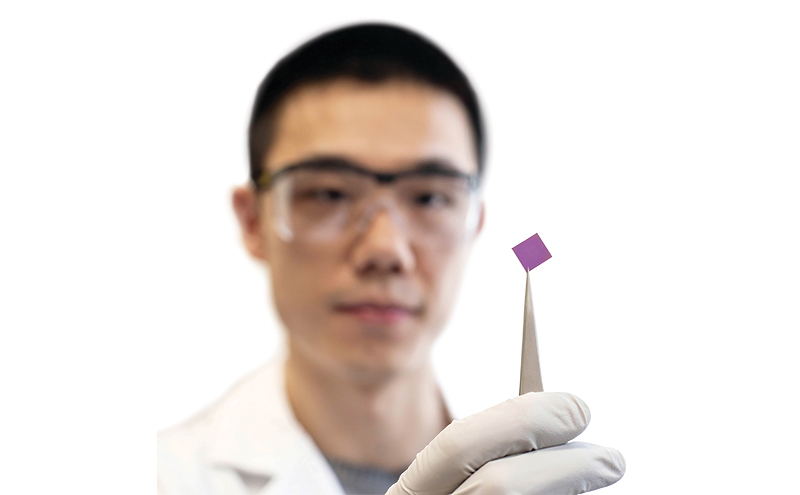

Graphene is a paradox: it is the thinnest material known to science, yet also one of the strongest. Now, research from U of T Engineering shows that graphene is also highly resistant to mechanical fatigue.

The team — including mechanical engineering PhD candidate Teng Cui, mechanical engineering professors Tobin Filleter and Yu Sun (Canada Research Chair in Micro and Nano Engineering Systems), materials engineering professor Chandra Veer Singh and collaborators at Rice University — combined computer simulations with physical experiments. In the lab, they stretched a sheet of graphene over holes only a few micrometres in diameter, like the head of a tiny drum.

Using an atomic force microscope, they applied anywhere from 20 to 85% of the force that would break the material. “Even at 70% of the maximum stress, the graphene didn’t break for over a billion cycles,” says Cui.

Graphene-containing composites are already finding their way into sports equipment such as tennis rackets and skis, and in the future may be used in cars or in aircraft.

“Until now, nobody had measured the fatigue behaviour of the underlying material,” says Filleter. “Now that we have that, we should be able to design composites that work even better.”

Tiny features, big challenges

For nearly 30 years, a partnership between Hitachi High-Technologies Canada (HHTC) and U of T Engineering has enabled advanced analysis of a wide range of samples — everything from volcanic glass from the bottom of the ocean to rocks that the Apollo astronauts brought back from the moon.

HHTC designs and deploys electron microscopes, and some of their most advanced equipment is at the Ontario Centre for the Characterisation of Advanced Materials (OCCAM). This interdisciplinary research centre, co-located in the Departments of Material Science & Engineering and Chemical Engineering & Applied Chemistry, is built around state-of-the-art electron microscopy and surface characterization tools.

Involving both equipment and personnel, the partnership enables HHTC to draw on the practical challenges that users are trying to address to catalyze the development of new microscopy technologies. OCCAM is the first place that these technologies are deployed, and the two-way partnership continuously yields new protocols and procedures. By remaining at the forefront of electron microscopy, OCCAM enables its users — from across U of T Engineering and beyond — to gain insight into the natural world and design better devices, from dental implants to microchips, solar cells, aircraft and much more.

“Many people don’t know it, but some of the most advanced instrumentation for analyzing materials are developed right here in Toronto,” says Professor Jane Howe, who worked at HHTC for more than 10 years before joining U of T Engineering’s departments of materials engineering and chemical engineering in 2018. “In large part, that is due to close collaborations between exceptional researchers and partners in industry.”

All water on Earth is part of the same cycle — and every drop matters. Yet around the world, water supply and quality are under increasing pressure from growing populations, industrial development and climate change.

U of T Engineering researchers are working together to break down chemical contaminants, develop low-cost solutions for sanitation and design more natural water management structures for cities. Together with our partners, we are ensuring a safe, accessible water supply for generations to come.

Why some cities turn off the taps at night

For more than a billion people around the world, running water is supplied by intermittent systems that turn on and off at various times of the week. Civil engineering professor David Taylor studies the design and function of intermittent systems — and how they fit into the global challenge of meeting international targets for human development and safe drinking water.

“These systems are chaotic,” says Taylor. “There are often pipes or valves that are missing from the official charts. We usually don’t know as much as we think we do.”

Rather than use complex hydraulic models typical of the industry, Taylor has developed a single equation that describes how a system behaves when consumers are satisfied versus when they are not.

In the unsatisfied case, turning off the pipes may save water, but it does so by leaving customers thirsty. In the satisfied case, demand tapers off and other effects, such as leakage, come to dominate the system, so turning off the pipes may cause more trouble than it’s worth.

“Without a way to decide which intermittent systems count as ‘safe,’ we don’t stand a chance of hitting our 2030 global goals for access to clean and affordable water,” he adds. “The model can help guide us as we start to make the major infrastructure investments needed.”

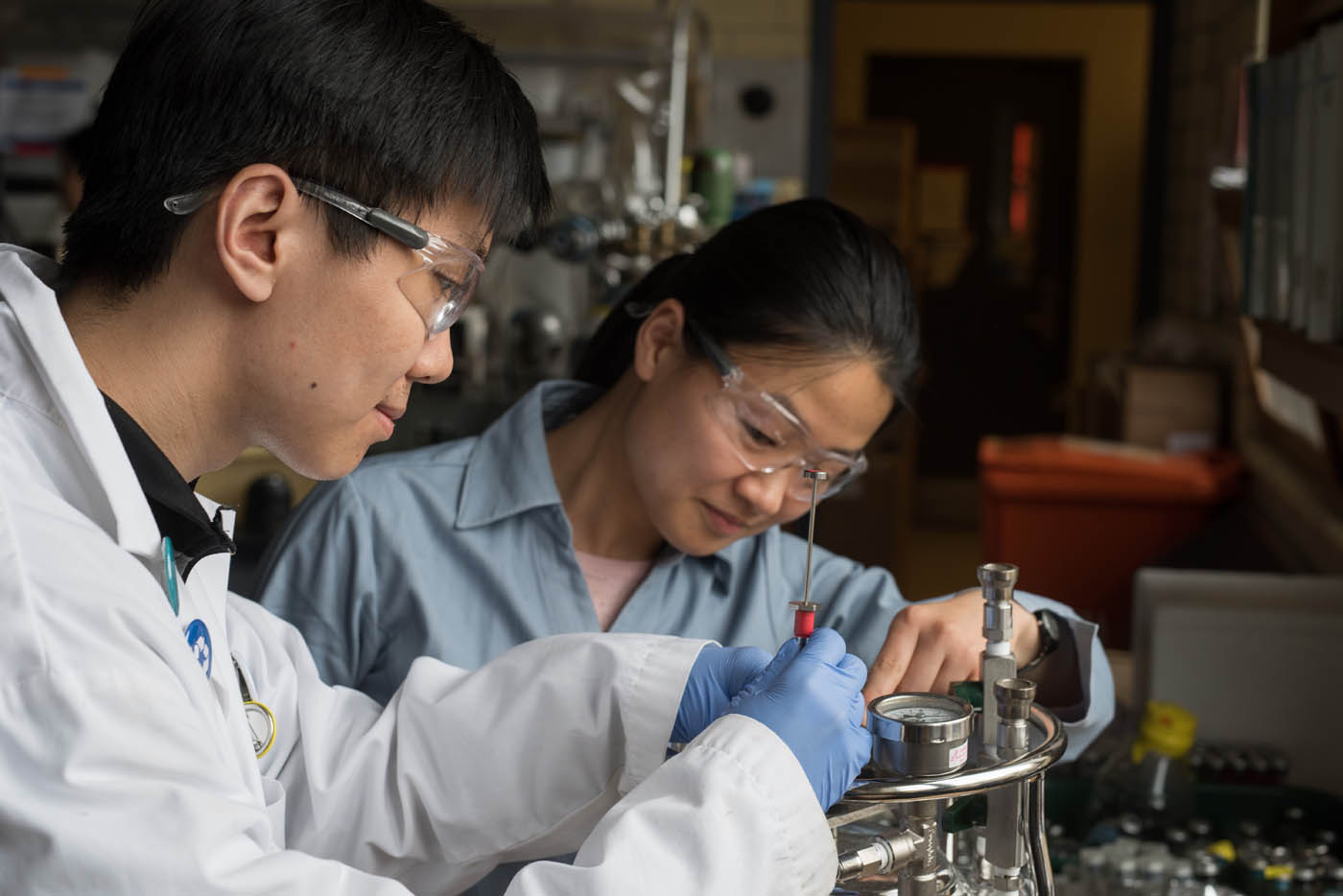

Pollution-eating microbes are ready for action

Chemical engineering professor Elizabeth Edwards, who holds the Canada Research Chair in Anaerobic Biotechnology, has spent years developing a potent mix of microbes that can break down toxic chemicals. Now, through spinoff company SiREM, she and her team are preparing to put them to work for the first time.

The bacterial cultures are designed to treat a set of contaminants known as BTEX — benzene, toluene, ethylbenzene and xylene — found in soil and groundwater where crude oil and its products have been used. Selected from natural organisms found at contaminated sites, the cultures are able to survive without oxygen, enabling them to be injected into deep aquifers.

The collaboration has a track record of success. Edwards and SiREM previously commercialized a culture known as KB-1, which was designed to break down chlorinated solvents widely used in dry cleaning and degreasing. If the new cultures are as successful, SiREM plans to add them to their arsenal to increase their share of the multi-billion-dollar global market for biological treatment of contaminants.

Doctors and medical researchers work closely with engineers to design better ways of diagnosing and treating disease. These partnerships enable us to cure what was previously incurable, extending and enhancing human lives around the world.

U of T Engineering innovations range from algorithms that point toward promising drug candidates to lab-grown tissues and organs that could one day be re-implanted back into humans to repair damage. They also include simple, low-cost diagnostic tools that reduce the need for complex lab equipment, especially in remote locations.

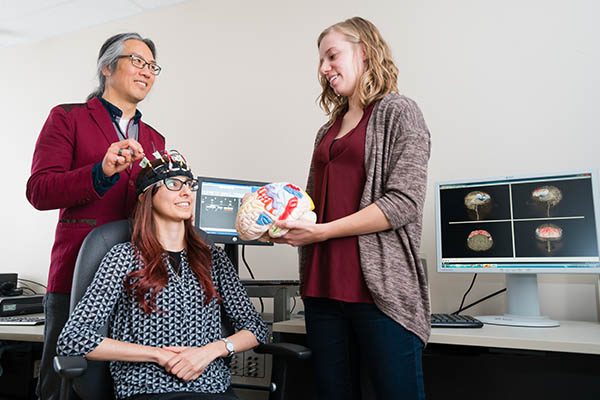

Smarter MRI scans for diagnosis and treatment

As stem-cell technology improves, researchers hope to one day repair damaged tissues and organs by implanting lab-grown replacements. Today, however, most implanted cells die, and a great deal of research focuses on what can be done to successfully integrate them into the body.

Biomedical engineering professor Hai-Ling Margaret Cheng and her team can help. They are developing substances that could enable the progress of implants to be tracked by non-invasive methods, such as magnetic resonance imaging (MRI).

“Prior to an MRI session, patients may need to intake a contrast agent, a substance that makes certain tissues or organs easier to see in the scan,” says Cheng. “If we could incorporate contrast agents directly into implanted tissues and scaffolds, we could non-invasively track their progress over time.”

Traditional contrast agents are designed to last only a few hours, and many of them cause side effects. Cheng’s approach of leaving them in the body for months on end would require re-designing these substances from the ground up, but the team is up to the challenge.

“As a patient, the last thing you want is to have an implant, and then have a highly invasive surgery a couple of months down the line to check whether the cells are still there,” she says. “If we can provide an alternative, it could be a game-changer for everyone who’s involved in regenerative medicine.”

Using genome-aware AI to discover new drugs

Most new drugs fail. U of T Engineering spinoff company Deep Genomics aims to change that.

Deep Genomics was created in 2015 and based on the work of electrical and computer engineering professor Brendan Frey, who holds The Edward S. Rogers Sr. Chair in Engineering and the Canada Research Chair in Information Processing and Machine Learning. It is the only company

to combine more than a decade of world-leading expertise in both deep learning and genome biology.

The company’s proprietary algorithms crawl through reams of data on the many genetic mutations that can cause disease, and make predictions about the properties of potential therapeutic molecules. Their AI is then used to design new compounds that are therapeutic candidates.

In the fall of 2019, Deep Genomics announced the first-ever therapeutic candidate discovered using artificial intelligence. The candidate has the potential to treat Wilson disease, a rare genetic disorder that causes an accumulation of copper in vital organs, and can be fatal if left untreated.

“Our vision is to develop genetic medicines more rapidly and more accurately than was previously possible,” says Frey.

Skule™ is just as much about what happens outside of class as what happens within it.

Student clubs, teams and affinity groups offer rich opportunities for students to apply their technical expertise to design challenges, gain global experience, develop their creativity and find a sense of belonging. From the National Society of Black Engineers (NSBE) to the Skule™ Orchestra, there is truly something for everyone.

In February 2020, the U of T chapter of the National Society of Black Engineers hosted NSBEHacks 2020, the only student-run Black hackathon in the GTA. (Photo courtesy Mohamed Hirole)

Stitch4Corona

Biomedical engineering PhD candidates Kramay Patel and Chaim Katz temporarily traded in their electrodes and amplifiers for sewing machines and cotton threads.

In March 2020, they launched Stitch4Corona, a volunteer-driven initiative to sew fabric face masks to help protect Toronto’s most vulnerable during the COVID-19 pandemic. Volunteers are provided a kit with enough pre-cut cotton sheets, metal wires and elastic loops to sew 11 masks — with the eleventh mask meant for the volunteer to keep.

Once the masks are finished, the Stitch4Corona team either picks up the masks or makes arrangements for delivery to a nearby drop-off location. In just one month, more than 200 volunteers stitched 2,000 masks for Toronto’s Michael Garron Hospital, several local walk-in clinics, as well as respite centres in the city.

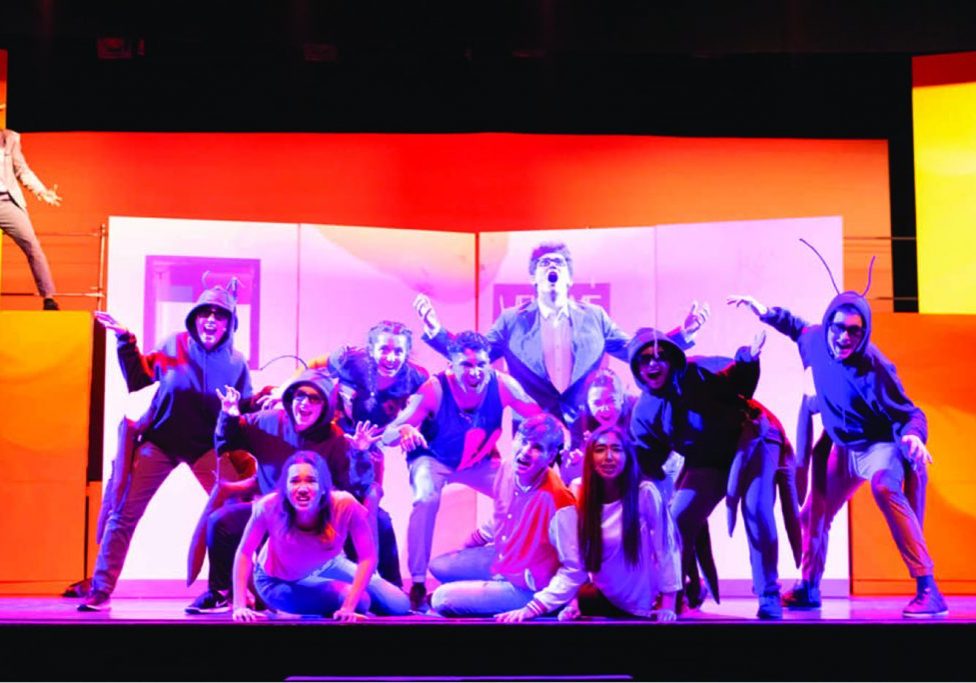

SKULE™ NITE ONLINE

This musical and sketch comedy revue has been a UofT Engineering institution for decades, and the show must go on, even during the COVID-19 pandemic.

While two performances went off without a hitch, subsequent live shows had to be cancelled due to physical distancing guidelines. Fortunately, the team was able to capture footage of their performance to create an online version of the show. The video was available from April 10 to 30 on a pay-what-you-can basis and attracted nearly 3,700 online viewers.

HUMAN POWERED VEHICLE DESIGN TEAM

In September 2019, UofT Engineering’s Human Powered Vehicle Design Team broke the world speed record for a tandem bike. Their speed bike, dubbed Titan, achieved a blistering top speed of 120.2 kilometres per hour, shattering the previous record of 117.61 kilometers per hour set in 2012.

The World Human Powered Speed Challenge is a global competition that takes place annually in Battle Mountain, Nevada, USA. UofT Engineering teams and alumni have historically dominated at the WHPSC, setting records in 2015, 2016 and 2017.

GRADSWE

This year, UofT graduate students launched GradSWE, the first official graduate student community of Society of Women Engineers (SWE) in Canada.

SWE is one of the biggest professional organizations in the world for self-identifying women engineers. Led by a team of volunteers, including civil and mineral engineering PhD candidates Sylvie Spraakman and Georgina Kalogerakis, and chemical engineering PhD candidate Anupama Sharan, the group aims to build a sense of community among women pursuing graduate studies in engineering and cultivate professional development opportunities.

CONCRETE TOBOGGAN

In January 2020, UofT Engineering hosted the annual Great Northern Concrete Toboggan Race for the first time since the competition was founded in 1974. Held at Snow Valley Ski Resort, near Barrie, Ont., the competition featured 21 teams, with the UofT team taking first place.

Equity, diversity and inclusion (EDI) strengthen the engineering creative process. Our Faculty is committed to fostering an environment in which each member of our community can excel, contribute and benefit from different perspectives.

In May 2019, UofT Engineering created the Office of Diversity, Inclusion and Professionalism. Led by Assistant Dean and Director Marisa Sterling, P.Eng., who is also president of Professional Engineers Ontario, this office joins several other bodies and positions within the Faculty that are dedicated to aspects of EDI.

Examples include the Dean’s Advisor on Black Inclusivity Initiatives and Student Inclusion & Transition Advisor (Mikhail Burke), Dean’s Advisor on Indigenous Initiatives (Jason Bazylak), the Engineering Equity, Diversity and Inclusion Action Group, and the U of T Engineering Positive Space Committee.

While there is much more to be done, U of T Engineering remains committed to enhancing equity, diversity and inclusion within the Faculty and the engineering profession.

On September 30, 2019, our community came together for Orange Shirt Day, an event to honour survivors and recognize the trauma caused by the residential school system. (Photo: Roberta Baker)

One of 15 posters created for Black History Month 2020. Visit www.uoft.me/BHM20 to read more community reflections. (Photo: Daria Perevezentsev)

Black inclusion at U of T Engineering

In February 2020, our Black Inclusivity Steering Committee (BISC) delivered its final report, Striving Toward Black Inclusivity. Its recommendations highlight a number of areas in which U of T Engineering could grow, improve or take a leadership role, such as the collection and sharing of data disaggregated by racial identity, and leveraging frameworks to facilitate diverse candidate pool formulation and consideration for prospective faculty and staff hiring.

Efforts are underway to take concrete action on these recommendations. For example, following the committee’s interim recommendations (delivered October 2018) U of T Engineering created a robust campaign for Black History Month in February 2020 featuring the voices of our students, staff and alumni through posters, our website and social media channels. We received more than 1,500 pageviews and 8,000 engagements on social media throughout the campaign.

OPEN DISCUSSIONS

These monthly events invite students, staff and faculty to discuss issues challenging equity, diversity and inclusion such as imposter phenomena or fostering inclusive spaces. In 2019–2020, four two-hour sessions were held, with a total attendance of approximately 240.

TOWARDS INCLUSIVE PRACTICES (TIPs)

These sessions provide staff and faculty with training to enhance equity, diversity and inclusion in their work. Examples include Identify, Assist, Refer training to recognize students in distress, and making teamwork more accessible. In 2019–2020, two sessions were held with a total attendance of approximately 80.

EQUITY & INCLUSIVITY DIRECTOR

Second-year Engineering Science student Savanna Blade served as Equity & Inclusivity Director of the Engineering Society in 2019–2020. She worked with 15 student groups and external organizations to make equity topics more visible and accessible to students, including facilitating student-run sessions on unconcious bias and consent, and providing equity training for other student leaders.

#WEREMEMBER

U of T Engineering hosted an event on December 6, 2019 to remember the 14 women whose lives were taken 30 years ago at École Polytechnique. As part of a national initiative, U of T Engineering was one of 14 engineering schools to shine a beam of light into the sky in a stand against gender-based violence and discrimination. More than 200 community members attended with another 300+ watching on livestream.

QUEERSPHERE BRIDGE BUILDING COMPETITION

As a part of Godiva Week in January 2020, Queersphere hosted a gingerbread cookie bridge-building competition, which brought together faculty members, staff and students from across the Faculty.

MENTAL HEALTH PROGRAMS OFFICER

Melissa Fernandes was recently appointed as U of T Engineering’s inaugural Mental Health Programs Officer. The newly created role will develop programs and resources to support student mental wellness and increase awareness of mental health challenges for students, staff and faculty.

U of T Engineering’s pre-university outreach activities inspire the next generation of global engineering leaders by enabling students in Grades 3 to 12 to experience science, technology, engineering and mathematics (STEM) in a way that is tactile and fun.

These in-school workshops, after-school programs and summer camps engage our partner communities across the Greater Toronto Area, and provide valuable opportunities for the undergraduate and graduate students who design and deliver them to develop their skills in leadership, communication, project management and team building.

Several of our programs focus on groups that have traditionally been under- represented in STEM, including Black students, Indigenous students and women.

Blueprint

Launched in the spring of 2020, Blueprint is an academic enrichment program designed for highly motivated Black students currently in Grades 9, 10 and 11 who are interested in careers in STEM with a strong interest in engineering.

Due to the COVID-19 pandemic, this program began with three virtual courses, online meet-ups and mentorship activities, offering participants exposure to research experts and current students at Canada’s top engineering school. The program had more than 50 participants from across Canada, and will transition to in-person meetings when circumstances allow.

STEM Day

The innovative approaches to STEM instruction developed by U of T Engineering’s outreach team are valuable resources for classroom teachers.

Throughout 2019–2020, Michael Waldman, a STEM teacher with the Toronto District School Board, was seconded to U of T Engineering as the STEM Educator in Residence. Through this new position, the Faculty hosted several events to further enhance collaborations between U of T and elementary school educators.

One of these events was STEM Day, which challenged graduate students in UofT Engineering’s Prospective Professors in Training program to design activities that communicated curriculum-relevant science and engineering concepts. Participants had the opportunity to learn about projects in fields from facial recognition technology to environmental remediation to advanced manufacturing.

“Those types of experiences can get students thinking about engineering in a different way,” says Waldman. “That’s especially valuable for the type of kids who might not traditionally have considered an engineering education. It’s a really exciting partnership.”

Awards & Honours

Between April 2019 and March 2020, our faculty received more than 30 awards and honours at the regional, national and international levels. In the 2019 calendar year, we received 16.4% of all awards presented to Canadian engineering professors, despite making up less than 6% of the nation’s faculty. View awards page »

One of UofT Engineering’s most beloved buildings isn’t on campus — it is located more than 100 kilometres north of Toronto, on the shore of Gull Lake, near Minden, Ont., and it’s about to get a major upgrade.

Since 1920, the two-week Civil and Mineral Practicals (CAMP) course has provided students with the opportunity to further their understanding of the vital interactions between the natural and built environments. On September 7, 2019, more than 100 attendees celebrated a century of Survey Camp. With a fantastic turnout of alumni, students, faculty and friends, the event showcased existing facilities at Gull Lake and marked a ceremonial groundbreaking for a planned Heavy Construction Association of Toronto (HCAT) bunkhouse and MacGillivray Common Room.

On June 26, 2019, more than 400 members of the U of T Engineering community came together to celebrate the transformative leadership of Cristina Amon, who served as Dean from 2007 to 2019. Under her visionary leadership, the Faculty has become a global leader in multidisciplinary research, education and innovation.

In recognition of Amon’s enormous impact and lasting legacy, alumnus Paul Cadario announced the creation of the Decanal Chair in Innovation, an endowed chair to be held by all future U of T Engineering deans that will seed innovative projects in perpetuity. A testament to her unwavering dedication to fostering innovation and collaboration, the Decanal Chair will be renamed in honour of Amon upon her retirement in accordance with University policy.

A gift from boutique intellectual property law firm Bereskin & Parr LLP is further enhancing programs at U of T Engineering’s Entrepreneurship Hatchery.

“Year after year, the creativity and drive of the students I see in the Hatchery’s programs amazes me,” said Isi Caulder, a Bereskin & Parr partner and co-leader of the firm’s AI patent practice group. A triple U of T alumna with degrees in engineering science, electrical and computer engineering, and law, Caulder has served as a dedicated mentor and advisor to teams for more than five years.

“In fields from AI to medicine to entertainment, I truly believe that the businesses and products they are inventing and refining today will become some of the technologies that will define our future, and I am thrilled to be a part of their process as they make that happen.”

The $50,000 donation is doubled via a match by the University of Toronto’s True Blue Fund. These funds enable the creation of flexible grants that

will be awarded to teams in the Hatchery’s programs and support their development.

A new, purpose-built facility for sustainability research is taking shape on the rooftop of the Wallberg Building.

Designed to foster bold experimentation and act as a catalyst for accelerating our research and training activities, the Sustainability Lab (S-Lab) is not only a space in which to do research, but part of the research itself.

S-Lab will feature a 550 square metre rooftop solar array and advanced environmental sensors that can inform innovations to the built environment. Features such as smart lighting with daylight dimming and advanced low-velocity fumehoods will reduce the facility’s carbon footprint, with a goal of net zero carbon.

At the core of S-Lab is an open concept space that encourages both structured and informal interaction. Students and researchers from more than a dozen lab groups will share tools, equipment and resources, catalyzing new ideas and new ways of thinking.

Philanthropic Support

Advancement results, May 1, 2019 to April 30, 2020

Gift designations, May 1, 2019 to April 30, 2020

Financial Highlights

$101.5M

Total research infrastructure funding and research operating funding, 2018–2019, an increase of $22.3M over the past five years.

$52.3M

Total graduate student funding, 2018–2019, an increase of $7.6M over the past five years.

$45 M+

Approximate value of infrastructure projects currently underway, either in design or construction phases.

$16.7M

Industry research funding for 2018–2019, an increase of $9.0M over the past five years.

$375.4K

Support distributed to student clubs and teams, 2019–2020.

$12.0M

Undergraduate financial assistance distributed in 2019–2020, supporting 1,641 students.

Share this page

Shortlink: uofteng.ca/2020